| Model | HP 3000 |

| Max. Flow Rate | 2m3 per hour |

| Filtration Rate | 0.01 micron |

| Turbidity | < 0.1 NTU |

| Inflow Pressure | 0.1 – 0.3 Mpa Measurement of |

| Connection | G3/4” |

| Filter Material | Food grade super membrane |

| External Casing Material | 100% SUS304 Stainless Steel |

| Life Span | Subject to feed water quality, water usage and handling |

HP 3000

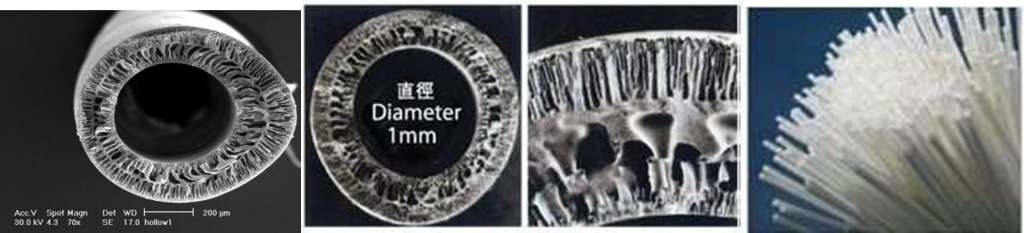

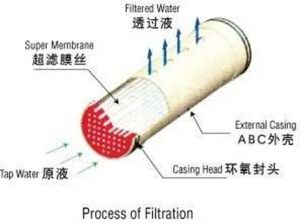

Membrane Structure

Ultra-filtration membrane cartridges operate from the inside to the outside during filtration. This means that process fluid (retentate) flows through the centre of the hollow fibre and permeate passes through the fibre wall to the outside of the membrane fibre. Tangential flow can help limit membrane fouling. Other operating techniques that can be employed with hollow fibre ultra- filtration membrane systems include back flushing with permeate and retentate reverse flow.

Before Filtration After Filtration

~ Bacteria: 0.22-4.00 micron ~ 0.01 micron

~ Virus: 0.02 – 0.35 micron ~ Clean & Safe water

~ Sediment: 200 – 10000 micron

~ Rust: 10 – 100 micron

~ Chemical: 0.02- 0.9 micron

~ Organic matters & Decay: 0.03-3 micron

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.